Reduce Downtime. Lower Costs, Ensure Compliance in Food & Beverage

In food and beverage manufacturing, reliability isn’t optional, it’s essential. Strict hygiene regulations, tight production windows, and increasingly complex traceability demands mean any equipment failure can result in serious downtime, safety risks, and product loss.

ShireSystem is a powerful, proven Computerised Maintenance Management System (CMMS) that helps food and beverage producers minimise disruption, improve asset reliability, and meet their compliance obligations. Whether you’re a high-volume bakery, dairy, beverage bottler, or ready meal producer, ShireSystem supports your journey from reactive fixes to fully optimised, compliant maintenance operations.

Start your journey today

Deliver Consistent Output, Reduce Wastage

The food and beverage sector requires a razor-sharp focus on hygiene, process control, and product integrity. ShireSystem gives you the tools to stay in control of your maintenance and compliance, with clear visibility into every asset, work order, and inspection.

Reduce Unplanned Downtime

Minimise unplanned downtime and prevent costly breakdowns across your food and beverage operations. Reactive maintenance often results in sudden line stoppages, product loss, and expensive emergency repairs. By adopting a proactive maintenance approach, you can keep production running efficiently, maintain quality standards, and protect compliance.

Lower Costs

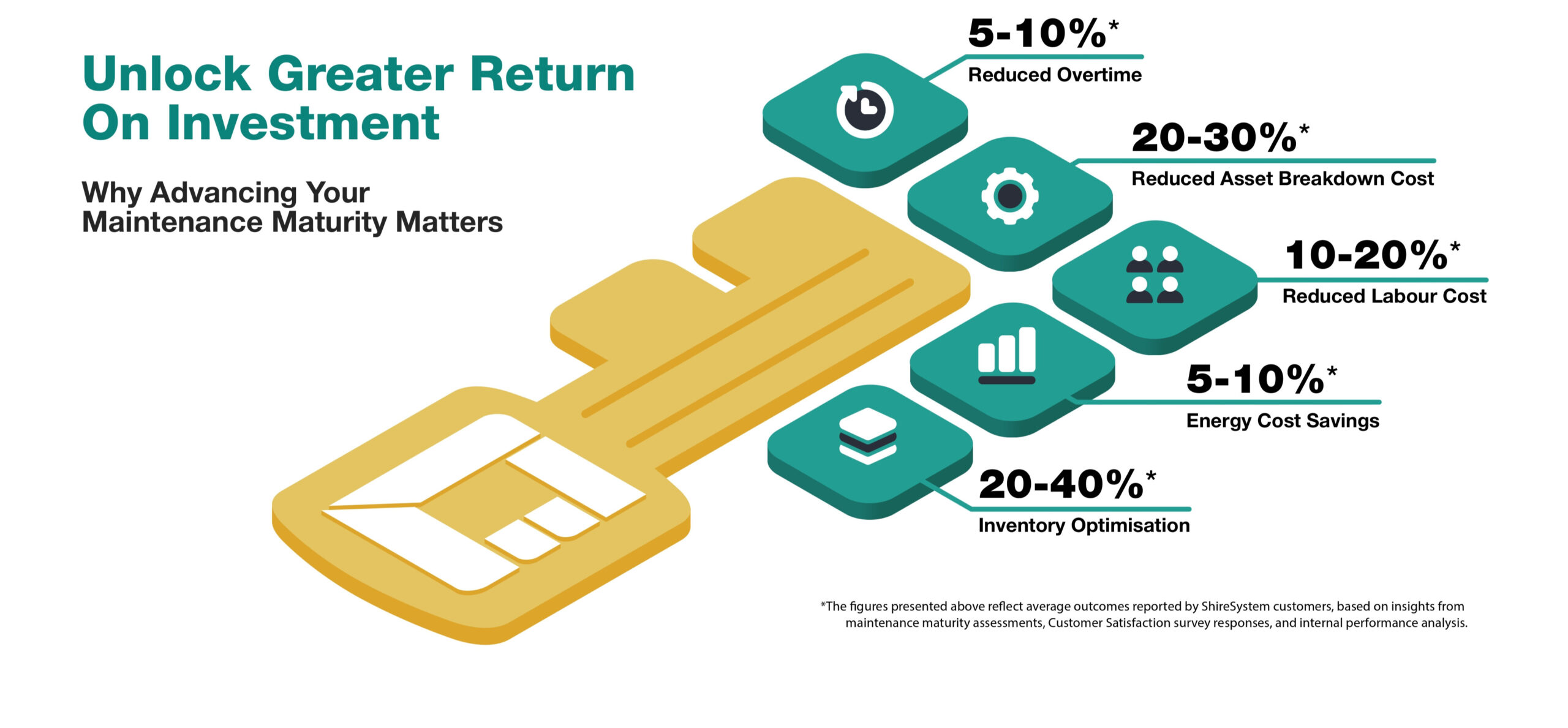

ShireSystem helps food and beverage manufacturers drive down costs by streamlining every aspect of maintenance management, from scheduling and work orders to inventory control and reporting. It reduces equipment downtime, extends asset lifespan, and ensures that production lines continue to operate smoothly and efficiently.

By supporting proactive, planned maintenance and reducing the need for reactive repairs, it helps lower labour, parts, and operational costs. Real-time insights and reporting also enable smarter, data-driven decisions, optimising resources, improving efficiency, and preventing costly production interruptions.

Improve Compliance

Strengthen compliance and maintain complete traceability across your food and beverage operations with a clear, auditable record of every maintenance task, inspection, and safety check. Automated reminders ensure statutory and regulatory procedures are completed on time, while real-time dashboards highlight any overdue actions before they become compliance breaches.

With full visibility and detailed reporting, teams can easily demonstrate adherence to industry standards and legal requirements during audits, reducing the risk of fines, product recalls, and reputational damage, while reinforcing a strong culture of safety and accountability.

Why Food & Beverage Manufacturers Choose ShireSystem

We don’t offer just software to food and beverage manufacturers, we partner with your operations to help transform them:

- Tailored implementation & onboarding

We work with your production teams to configure ShireSystem so it fits your environment, your needs and maintenance maturity ambitions. - Ongoing support & optimisation

We don’t “set and forget.” Our team helps you analyse performance, fine‑tune schedules, and adopt best practices. - Scalable & future‑proof

From single-site plants to multi‑site operations, ShireSystem supports growth, greenfield expansion, and evolving compliance requirements.

Tackling Food & Beverage Industry Challenges

With intense pressure to maintain uptime, protect product quality, and meet audit standards, food & beverage manufacturers need a CMMS that does more than schedule jobs. We recognise that food and beverage manufacturers face many maintenance challenges, including:

- Critical equipment failures

- High Repair & Reactive Maintenance Costs

- Under-utilised Preventive Maintenance

- Complex Compliance & Audit Requirements

- System Integration Challenges

- Environmental & Process Sensitivities

Improved Uptime

Keep critical food and beverage manufacturing equipment, like conveyors, fillers and chillers, operating at peak performance with well-planned preventative maintenance that helps you avoid disruptive breakdowns and extend asset life.

Better Compliance & Traceability

Demonstrate full compliance with your own internal and industry standards through digital audit trails, inspection logs, and maintenance history, all easily accessible and verifiable.

Cost Control & Waste Reduction

Reduce unplanned stoppages, overuse of raw materials, and reactive emergency repairs. ShireSystem helps you plan smarter and operate leaner.

Team Alignment & Accountability

Role-based access, approval proceses, and mobile job management improve communication and ensure that production, maintenance, and QA teams work in sync

Ready to Deliver Smarter Maintenance?

Whether you want to cut maintenance costs, strengthen food safety compliance, or improve asset longevity, ShireSystem CMMS will help you achieve your maintenance maturity objectives.

Contact us now to schedule a demo or discuss your needs.

Resources & Support

Choose the Right ShireSystem CMMS Plan for your Business

ShireSystem provides a range of CMMS plans tailored to suit organisations of all sizes, budgets, and levels of maintenance maturity.

Each plan is strategically designed to support your current needs, accelerate your progress, and deliver measurable returns on investment at every stage of your maintenance journey.

Essentials Complete foundation for proactive maintenance management with mobile capabilities and built-in knowledge management. £44 per user / month * based on 10 concurrent users | Professional Enhanced resource optimisation and data-driven decision making for maintenance operations that directly impact your bottom line. £120 per user / month * based on 10 concurrent users | Advanced Enterprise-wide maintenance orchestration with advanced compliance, and system integration capabilities. £197 per user / month * based on 10 concurrent users | Expert Complete maintenance ecosystem customisation with integrated procurement, and brand alignment for maximum organisational fit. £254 per user / month * based on 10 concurrent users |

*Save More as You Grow – The price per user drops with every additional licence